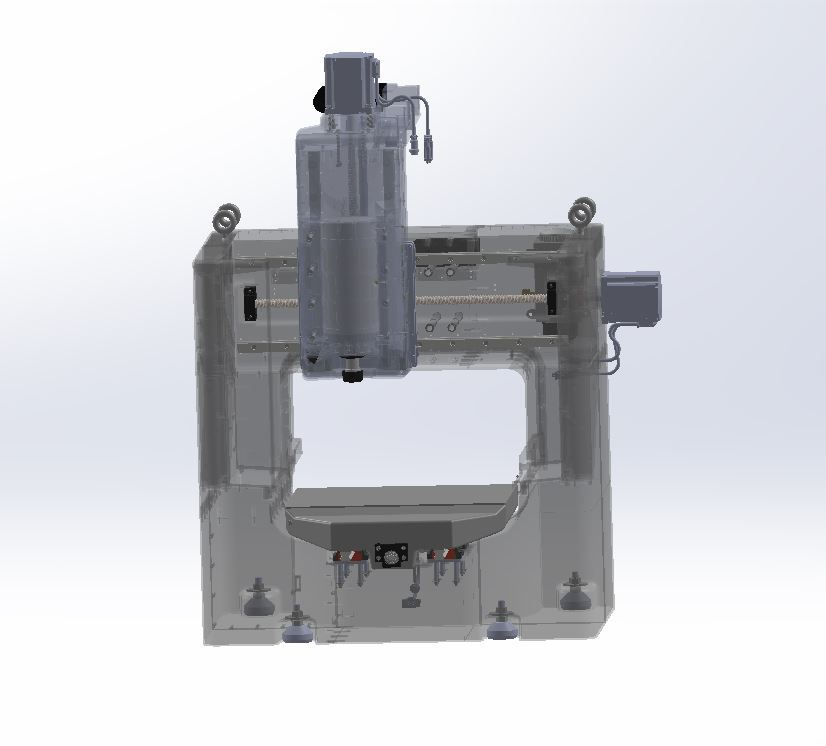

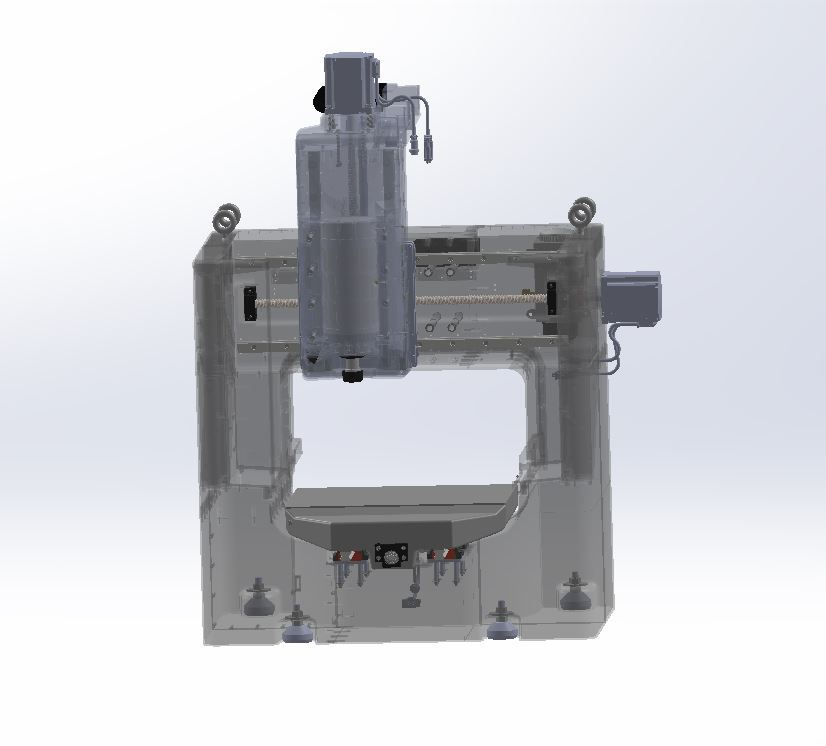

CAD model of the full machine

Headstock cast and partially assembled

Welded steel table (primed but not finished) for holding the machine and housing electronics/coolant

CAD model of the full machine

Desktop Milling Machine

For the past year, I’ve been working on building a desktop CNC machine. The machine’s structural components are made by casting an epoxy-silica composite into permanent 3D-printed shells. To hold the precision hardware accurately during casting, I use inexpensive but precise fixtures. My goal is to develop this method into a cost-effective, accurate approach for creating DIY CNC components without requiring precision machining.

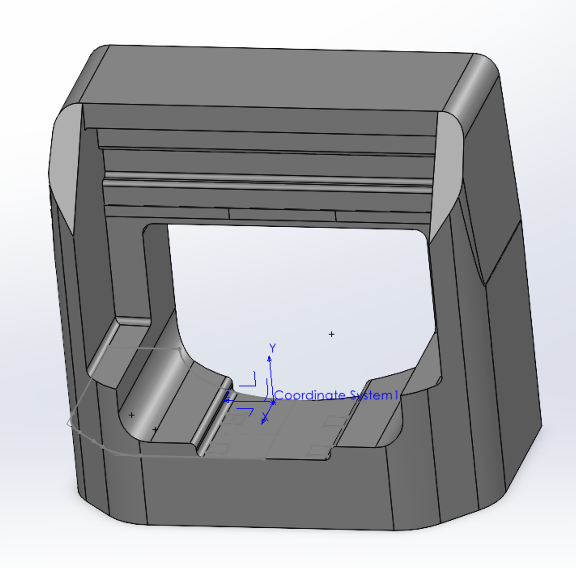

So far, I’ve cast the bed and headstock components with promising results. That said, this project has been highly challenging (and ongoing), and there are still several areas where I need to refine both the process and design.

To design the frame of this machine, I utilized various simulation techniques, including finite element analysis (FEA) and topology optimization. The manufacturing process I’m employing provided greater flexibility to optimize the shape of the machine components. To the right you can see some of my simulations and how they informed my frame prototype models as I progressed through the design.

I also designed and built a steel table to house the machine's coolant/electronics, and allow the machine to be moved. The top of the table (along with the machine) can be disconnected and slid into a pickup truck bed.

I recently attempted to cast the bottom half of the machine frame. Unfortunately there were a number of issues that ultimately resulted in the component being unusable. While I hoped the process would work on the first try, I was also anticipating that making this component might take a few attempts. Some of the problems I encountered are below:

-

The shell components were bowed out too much during casting.

-

The rebar was difficult to position.

-

My procedure for inserting and aligning the machine bed mounting points did not work due to component misalignment.

-

The resin leaked out of the bottom of the casting.

Currently I am working on a plan to fix the issues seen above. While there is some planning left to do, the following changes will be made.

-

The rebar will be mounted to the shell with thin 3D printed fixtures, both holding the rebar in place and helping to prevent the shell from warping.

-

Other structural elements will be temporarily fastened to the shells exterior where needed.

-

The casting procedure will be changed so that the machine bed mounting points can be added after the main casting in a secondary step.

-

The shell will be sealed before casting with resin and/or caulking

-

Faster curing resin will be used, and the composite will be mixed more thoroughly